Food Engineering Magazine features Rheonics viscosity solutions – “Beyond flow, level, pressure and temperature – New sensors, novel solutions”

Overview

Food industry focused magazine – Food Engineering Mag (https://www.foodengineeringmag.com/) publishes a feature article covering the Rheonics inline viscometer SRV alongside other new process devices on the horizon. The article discusses why food and beverage industries need to look beyond the basic four sensors (flow, level, pressure, temperature) to gain insights into their industrial processes and continue to stay competitive.

Title: “Using sensors to improve processes”, Tech Update: Beyond flow, level, pressure and temperature—New sensors, novel solutions

Featured: Rheonics, Allpax, Brooks Instruments, Festo, CHL systems, ECS Solutions, Endress+Hauser USA

Find the link to the the publication.

Conclusion/Article Summary

Today, sensors are everywhere. There are proximity sensors, accelerometers, gyroscopes, magnetometers, biometric devices, IR and temperature sensors, humidity devices and even oximeters in your smartphone (though you may not want to depend on the accuracy of a smartphone-based oximeter).

Besides the basic four (flow, level, pressure and temperature) sensors used to provide a window into industrial processes, there’s a myriad of other sensing devices that you find in everyday products—from toys to dishwashers and to automobiles. If your food or beverage operation isn’t making widespread use of sensors to monitor your process, you can’t expect to remain competitive for long—because as they say, “you can’t control what you don’t measure,” and you can’t expect actionable data from your process without them.

Mass flowmeters provide the precision and accuracy you need for exact metering of ingredients into a product, and viscometers can help you get control of tough non-Newtonian fluids—think sauces or batters. There are more sophisticated in-line/on-line sensors that can measure alcohol levels, fat content, molecular constituents and much more. With some ingenious engineering and the right sensing devices there’s no reason not to have control of your process.

Rheonics responses to FE

Rheonics response to the questions from FE for the article titled: Tech Update: Beyond flow, level, pressure and temperature—New sensors, novel solutions.

Q1: What types of sensors do you make? What food/beverage applications do you focus your solutions?

Response:

Rheonics develops, builds, and sells density and viscosity sensors and automated solutions that are used in a broad range of applications from food processing to petrochemicals.

Our sensors are used in various stages of food processing like transport, mixing and coating involving both Newtonian and non-Newtonian fluids.

Rheonics density and viscosity meters are widely used by global machine builders and manufacturers for monitoring batter mixing and coating, chocolate conching & wafer coating, creams, milk, yogurt, mayonnaise, sauce manufacturing, enteric coating for animal food products, monitoring alcohol and sugar content in wines and beverages, and for automating wastewater streams.

Q2: Describe a challenging food/beverage application where you used conventional sensors (e.g., flow, level, pressure, temperature, pH/conductivity, turbidity, accelerometers, etc.) to create a novel solution?

Response:

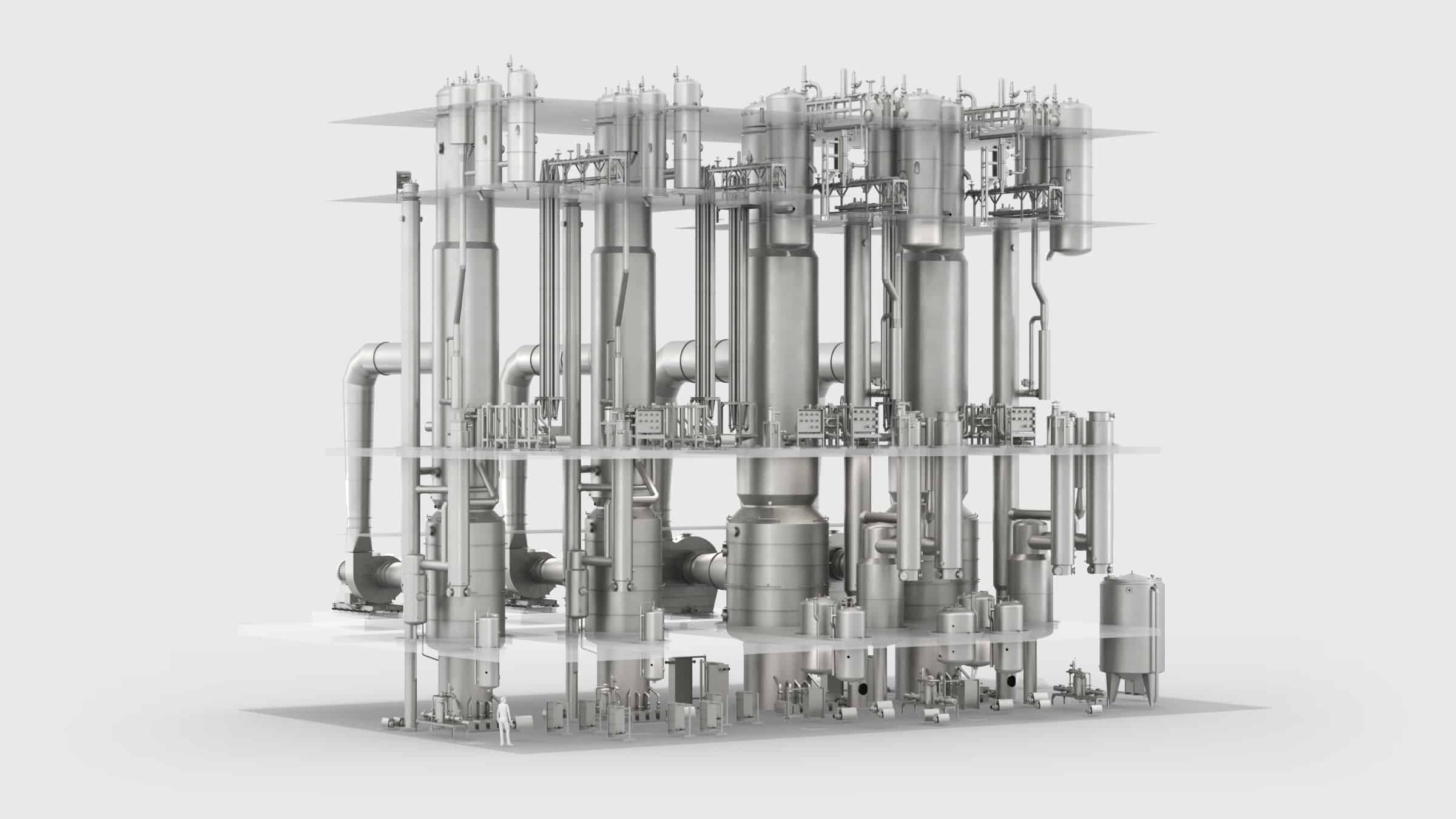

One of our customers is an American supplier of batter mixing and coating lines providing fully automated lines for French fries, chicken nugget, fish fingers, potato crisps coating. They were using pumps and pressure gauges to monitor the consistency of the batter to coat these products. The issue was the wide variation and constant need for calibration of the lines every time a batter mix was changed. This made the system highly technical for operators to use.

After a week-long trial, they adopted the Rheonics inline SRV for real-time monitoring of the batter mix. The sensor used came with hygienic connection and was installed directly in the mixing line as well as on the coating line. Today, the sensors are offered as a standard equipment on most of their mixing and coating lines ensuring single click monitoring and control of the batter.

Q3: Describe a challenging food/beverage application where you used more sophisticated sensors to create a solution?

Response:

One of our Swiss customers needed to create the “perfect” chocolate wafer bars, the bottleneck was the consistency of the chocolate and cream layer which needed to be applied in the exact thickness to ensure the correct final thickness of the wafer and to give the perfect crunch to their customers!

Rheonics inline viscometer SRV was installed by the customer on their production lines to monitor the chocolate and cream mixture to ensure the viscosity of the mixture was controlled within tight limits to allow consistency of coating. The chocolate-cream-nuts mixture was a complex fluid with air entrapped and the customers had not found any instrument that was able to give reliable and repeatable measurements before using the SRV.

Q4: In the future, what types of once-exotic sensors will be commonplace? How will manufacturing techniques make these sensors affordable? How about common sensors for flow, level, pressure, temperature, etc.?

Response:

Viscosity is a property that is affected at the molecular level and has tremendous amount of information about the process but has been hard to quantify reliably with existing instruments. It provides insights on the properties which matter the most in case of food products – texture and consistency. These properties influence taste, aroma, flavour and the ‘mouth-feel’ and ‘make or break’ product reception for consumers.

Major constraint to adoption of viscometers in food industry was two-fold: first a lack of robust, inline, repeatable viscometers and second the lack of integrated plant control systems capable of making good use of viscosity information in the overall control strategy. There was always a perception that though food rheology is important, it is a difficult subject to monitor reliably.

Main drivers for adoption:

- Wide applicability: Most food and beverages manufacturing processes benefit from inline viscosity management – dairy products – chocolates, yogurt, butter, creams, cheese, milk; batters, mayonnaise, sauces, alcohol, wines and food coatings.

- Supporting continuous production monitoring, quality control and consistency across batches

- Food 4.0 – most companies do not see data on their processes as a luxury anymore but rather as a critical requirement that directly affects their bottom line. A combination of reliable viscometers from Rheonics, wider adoption of industrial control systems in food processes and need to respond fast to changing consumer habits creates a win-win for automation solution providers like Rheonics, food equipment manufacturers and ultimately the food producers.

Q5: How will software play a role in the future of sensors? Will it be on-board and just part of the device? Will it provide for the monitoring of calculated process variables from measured (sensed) variables?

Response:

Software is going to play a key role in the future of sensors and the endless possibilities it would offer the factory engineers in terms of acquiring & analysing process data, detecting events which need intervention, optimizing their processes and gathering insights about the factory processes which have both short- and long-term implications.

There are a range of applications in the food industry, and it is important to understand that each application in unique in terms of the process goals, norms and regulations, product changeovers and factory engineers experience, common factory floor practices and knowhow.

The way the user inside the factory interacts with the sensor data is going to heavily rely on how best the software and the deployed data processing algorithms are suited to take care of the needs of that application. Therefore, software bundled with the sensors needs to provide for the monitoring of the calculated process variables from the measured variables according to the specific application/industry. This is supported by smart sensors, like from Rheonics, which use a combination of edge and cloud to enable deep process knowhow not possible from traditional sensors.

Intuitive software ensures an easier learning curve for factory managers, operators, and engineers to smoothly interact with the software and reap the full benefits of Industry 4.0 and automation technologies.

Q6: Will most sensors have a wireless option? Are there any applications where sensors can derive their power from vibration, light (e.g., solar), etc.

Response:

Mixing is fundamental to manufacture of many products, though in many cases it need not be a precise operation. However, in other cases it is more of an exact science; under-mixing can cause uneven distribution of component materials (non-homogeneity) and over-mixing may change the state of the product. While using sensors (for example viscometers) to precisely control and monitor mixing process, it is possible that the required install location is extremely constrained to accommodate wires being attached to the sensor and wireless would be a better alternative from installation perspective. We have seen such requests from customers we have already worked with, for example in chocolate conching vessels.

In such cases, wireless techniques make the installation and operation simpler. For example, without a physical connection, it is possible to use wireless link to both send power to the sensing element and receive measurement signals from it.

Depending on the application, deriving power from vibration, heat, flow or solar may also be feasible options. The biggest bottleneck so far in wider usage of energy harvesting technologies is the low power output of harvesters and high-power requirement of sensors. Advanced low-power sensors being created today are deriving knowhow from pacemakers and hearing aids to reduce their power budget which makes self-powering a medium-term possibility.

One key advantage of wireless and self-powered sensors is the significant reducing in installation cost of sensors. Today, 70-80% of the project budget for sensor goes towards installation so taking the wires out could reduce this dramatically and be the game changer that industry needs to adopt pervasive sensing.

Applications - Food & Beverages Industry

Inline Viscosity Monitoring for Atomization Applications

Atomization is a process used to break up a liquid into fine droplets, usually done by forcing it through a nozzle, sometimes helped by a high-velocity or high-pressure gas. Familiar examples include perfume sprays, garden hoses, and aerosol deodorants. Viscosity…

Mayonnaise Production and Rheonics Inline Viscosity Monitoring

Mayonnaise, a globally enjoyed condiment, is a classic oil-in-water emulsion, distinct from water-in-oil emulsions like butter and margarine. Its rheological properties, which influence consumer perception of texture and flavor, are crucial for its functionality in various culinary applications, from salads…

Milk of Lime (MOL Slurry) – Real-time monitoring and controlling optimum concentration

For process engineers, it's essential to develop an efficient and reliable method to monitor and control the milk of lime slurry in the production of the target product. The key to this process is to find a method that maintains…

Inline viscometers boost efficiencies of spray drying processes in milk powder manufacturing

The process of converting liquid milk into dry powder involves removing most of the water. The amount of water removed is many times greater than the amount of water in the finished product. Significant changes occur to the properties, structure,…

Cheese coagulation monitoring and cutting automation with inline viscosity measurements

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure consistency of texture and product-feel Data captured and processed by Rheonics viscometers helps you reduce variation significantly leading to a…

Optimizing non-Newtonian mixing applications with viscosity management

Key advantages of viscosity management in mixing applications: Accurate and efficient mixing operations – significant savings in material costs and energy Seamless product change-over: agility in dealing with different and new product variants and product provenance Compliance with regulations Optimizing…

Continuous monitoring of frying oil degradation in industrial food fryers

Summary: a single sensor to monitor effects of oxidation (TOTOX), fatty acid (TBA), and Polar compounds (TPC) on frying oil health and performance. Don't just test or sample, monitor throughout the frying process.

Optimizing liquid packaging, filling operations with inline viscosity management

Challenge Fluctuations in liquid products consistency in packaging, filling, dispensing operations means companies run risk of underfilling (which can be a breach of regulations and may attract penalties) or overfilling (which means 1000s of tons of extra materials could be…

Controlling the rheological behaviour of dairy food items to create consistent products – cheese, cream, ice-cream, milk, butter, yogurt

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure consistency of texture and product-feel From raw materials to end-product, rheological characteristics at every step of the processing is important…

Online viscosity monitoring for quality control in emulsions formulation, testing and processing

Emulsions are used in almost every aspect of daily lives. Their processing and development expands across many industries – chemicals, coating, food, cosmetics, adhesives, industrial fluids, pharmaceutical products, oil & gas.

Batter mixing and coating: Using lab rotational viscosity measurement for real-time process control with an inline viscometer

Customer application of the Rheonics SRV sensor to measure batter viscosity in a batter mixing and coating system is an established and widely used method to ensure batter consistency. Customers have traditionally relied on rotational viscometers to measure viscosity of…

Wastewater management in beverage and food processing with inline viscosity monitoring

Food and beverage industry is one of the key industrial segments and major contributor to global economic and societal growth. In the EU, it constitutes the largest manufacturing sector in terms of turnover, value add, and employment. However, the sector…

High quality Swiss chocolates rely on in-line viscosity monitoring for consistent rheology & texture

The chocolate confectionery industry is a sector that is not restricted by age or nationality; therefore, the growth of this industry is extremely high worldwide. The popularity of chocolate is almost certainly due to its unique eating characteristics. It melts…

Monitoring enteric coating for pharmaceutical products and livestock feed

An enteric (delayed-release) coating is a barrier applied to oral medication that controls the location in the digestive tract where it is absorbed. The term “enteric” refers to the small intestine; therefore, enteric coatings resist breakdown of medication before it…

Mixing Process Management

Mixing is the fundamental step in the manufacture of many products. Even though it may not have strict precision requirements, over-mixing still is an unnecessary waste of energy and time. In most cases however, mixing is more of an exact…

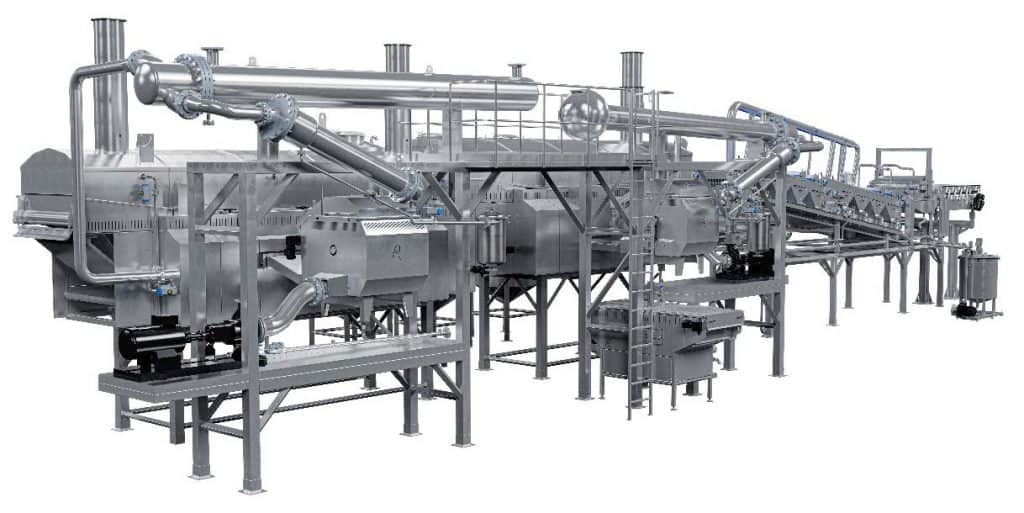

Batter preparation and coating process control

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts, biscuits, meat, breads, pancakes, etc. When used as coating, the batter is typically applied by dipping, or spraying onto continuous…

Yogurt quality control and optimisation

In the food processing industry, manufacturers are looking for two things - taste and texture. Texture is the “feeling” in the mouth when the product is eaten, and it is usually assessed by measuring the product’s viscosity. In this area,…

Rheonics sensors for transitioning to Food 4.0

Closed quality control loops and the increasing degree of viscosity automation enabled by the SRV viscometers add value to the production process in terms of quality, consistency, reduced wastes, efficiency and productivity. Human error is avoided, and fully automatic correction of any deviation in the manufacturing process becomes possible.

Data provided by the Rheonics viscometers and integrated solutions helps to accelerate learning curves and accommodate more frequent food product composition changeovers, contributing to a more resource-efficient, economical and greener manufacturing process.

In cases where asset productivity and OEE are key and maintenance costs are significant, actionable data provided by the viscometer solution helps food manufacturers cut down on process interruptions with predictive maintenance for production tools and machines. Forecasting potential downtime events and quality diagnosis are enabled by data provided by the sensors.

To know more about why food manufacturers are looking to integrate automation solutions in their production/factory floors, please read our article titled – “Digital food processing – drivers for manufacturers’ embrace of Industry 4.0”

Food Engineering Magazine: Inline viscosity sensing provides better batter control

Coupled with Industry 4.0 technology, inline sensing means no more rushing grab-samples to the lab, introducing quality issues with food products.

Digital food processing – driver for manufacturers embrace of Industry 4.0

Temperature fluctuations, mixing equipment condition, type and conditions of substrates, batter formulations, process step interactions and mixing time parameters can all alter the product quality and performance across batches in batter mixing and coating. In thin-margin sectors like baked goods,…

Unique advantages with the Rheonics SRV sensors

Rheonics sensors have built-in temperature measurement, permitting the temperature of the batter to be monitored at the point of application. This permits the viscosity readings to compensated for temperature, which is essential for ensuring consistent production through typical daily and seasonal temperature variations.

There are many benefits to using an inline viscosity sensor like the SRV for food applications. and some include:

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline with all standard CIP processes, or with a wetted rag, without the need for disassembly or recalibration

- No moving parts to age or foul with sediment

- Insensitive to particulate matter; no narrow gaps to foul with particulates

- All wetted parts are 316L stainless steel—meets sanitary norms with no corrosion problems

- Hygienic, sanitary design for food and beverage applications—available in tri-clamp and DIN 11851 connections for easy operation and cleaning

- Certified under ATEX and IECEx as intrinsically safe for use in hazardous environments

- Wide operational range and simple integration—Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

Food manufacturers strive to satisfy consumers’ often cited several textural and mouthfeel properties as the basis for why they like the “taste” and how the texture and mouthfeel, combined with health consciousness and demand for clean-label products influences continued consumption decisions. Viscosity is important in preparation and application of all types of batter – adhesion, cohesion and tempura batters.

Key takeaways:

- Vibrational viscometers, such as the Rheonics SRV, come closer to matching the high shear rates in batter coating than do rotational or cup viscometers. Therefore, measurements with the SRV come closest to predicting the behavior of batter under actual coating conditions.

- Inline viscosity control with the SRV and Rheonics Production Monitoring & Control system enables continuous viscosity control, making necessary dilutions in real time. Consistency is guaranteed regardless of temperature fluctuations, mixing equipment condition, type and conditions of substrates, batter formulations, process step interactions and mixing time parameters.

- Rheonics SRV and Production Monitoring and Control system control true temperature-compensated viscosity, which is essential for ensuring consistent production through typical daily and seasonal temperature variations.

Using the SRV sensor in batter mixing or coating line results in improved productivity, profit margins and regulatory compliance.

Once the process parameters are established, there is little effort required to maintain the integrity of the process. Operators can rely on the tight control provided by the Rheonics batter quality management solution and reap benefits not only in production, but also the product R&D stage when the formulation parameters are established. This enables the operator to gain competitive advantage as production is scaled up to meet increasing demand.

Rheonics density meters and viscosity meters are available as probes and flow-through systems for installation in tanks, process lines and reactors. All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.