7TH INTERNATIONAL SYMPOSIUM ON FOOD RHEOLOGY AND STRUCTURE : A novel process viscometer for food rheology applications

Overview

The International Symposium on Food Rheology and Structure (ISFRS) was hosted by the Institute of Food, Nutrition and Health at ETH Zürich.

The International Symposium on Food Rheology and Structure addresses the needs of food rheology and structure researchers. The symposium is devoted to rheology of food and related systems, to food structure and structure analysis, and to the complex relationship between food processing, structure, rheology and resulting food quality. An overview of the state of the art and a detailed focus on recent problem areas are given by the opening lecture and several keynote lectures that are presented by well-known scientists.

Dr. Joe Goodbread, CTO of Rheonics delivered a talk on – “A novel process viscometer for food rheology applications”; citing the use of SRV viscometer in food rheology applications.

Abstract

Vibrational process viscometers have been known for nearly 60 years but have found only modest application in food manufacturing processes, where control of product consistency is a high priority. This is due to the ingrained belief on the part of process operators that only measurements defined shear are capable of predicting the behavior of the usually non-Newtonian, often inhomogeneous products that they manufacture. A new instrument, the Rheonics SRV process viscometer, is descended from a line of vibrational viscometers that have found wide acceptance in the food process industry because they have proven themselves to be capable of controlling consistency in complex processes such as batter mixing, cheese coagulation, and beer mashing. The SRV builds on this heritage and adds to it a novel balanced resonator structure that makes it compact, simple to install, and free from the sensitivity to mounting conditions that has plagued earlier designs that lack its symmetric structure. Since vibrational viscometers function by measuring the rate of energy loss of a resonator immersed in the fluid under test, any additional energy losses due to vibrations transferred to surrounding structures place limits on the stability and reproducibility of the instrument’s measurements. The Rheonics balanced resonator (patent pending) ensures the highest possible reproducibility and stability in a resonant instrument by eliminating transmission of the resonator’s vibrations to surrounding structures. Further improvements to traditional vibrational viscometers include patented systems for rejection of ambient vibration due to pumps and other process machinery, as well as advanced electromagnetic transducers with unprecedented rejection of magnetic interference from neighboring machinery. The Rheonics SRV has already proven itself in a complex slurry-coating process line for which the operator initially believed that only a rheologically accurate instrument could bring the process under control. The operator found that the high sensitivity and stability of the SRV enabled control of the process by a single point measurement, whereas a battery of other instruments capable of measuring density and solids content were not sufficiently sensitive to measure the small variations in the process stream that were crucial to a uniform, adherent coating.

Applications

The SRV can be used wherever one-point measurements of apparent viscosity are required, whether in Newtonian or non-Newtonian fluids.

Applications include:

- Batter mixing

- Heavy fuel oil viscosity control

- Slurry coating process monitoring and control

- Pumping optimization

- Polymerization monitoring

Exploration of vibrational viscometry for rheological measurements

- Vibrational viscometer seems like an unlikely candidate for rheological measurements:

- Shear takes place in a thin boundary layer around the probe, rather than in the bulk fluid

- Shear is oscillatory, changing direction with the frequency of the probe’s vibration – roughly 7.4 kHz. for the Rheonics SRV.

- Sensor is effectively immersed in a semi-infinite volume of fluid, so that the velocity gradients are undefined.

- On the positive side:

- They are very stable

- Although the shear rate is unknown and unknowable, it is repeatable, so that vibrational viscometers are good for keeping the flow properties of a fluid constant in a process environment

Superimposing a bulk shear field on a vibrational viscometer can yield useful rheological information

- Observation: When a vibrational sensor such as the SRV is placed in a highly shear rate-sensitive material like tomato ketchup, its indicated viscosity fluctuates strongly as the probe is moved through the material.

- This suggests that if the sensor were placed in a uniform, controllable shear field, changing its shear rate could give information about shear-sensitive properties of the fluid.

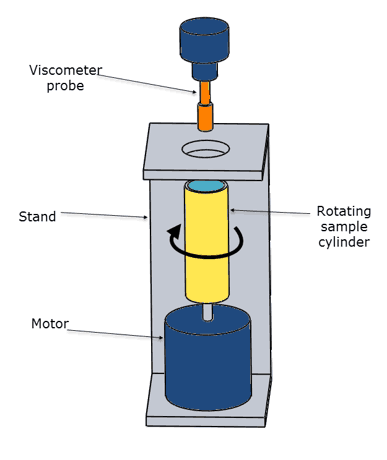

A simple superimposed-shear “rheometer”

- A sample cylinder is rotated about its axis by a controllable-speed motor

- The vibrational viscometer probe is immersed in the fluid

- The indicated viscosity of the fluid is recorded as the rotation rate is varied

The “ketchup meter”

- A Rheonics SRV viscometer is immersed in a cylinder holding a sample of tomato ketchup.

- A computer-controlled motor (below the wooden platform) rotates the sample at a series of fixed rates and durations.

- The viscometer control box transmits the measured viscosity values to the computer.

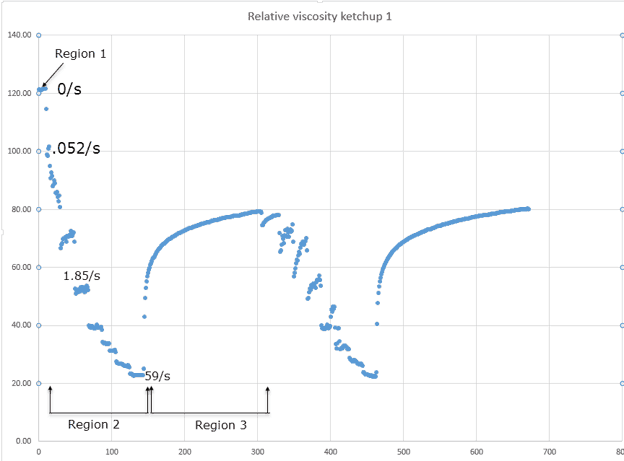

Superimposed shear behavior of ketchup

- Indicated viscosity in stationary cylinder is about 120 mPa.S. (Region 1)

- As cylinder rotates, indicated viscosity falls. Each step is a doubling of rotation rate. Viscosity approaches an asymptote (Region 2)

- When rotation is stopped, viscosity slowly increases to a new asymptotic level (Region 3).

- Certain features of this behavior are accurately repeatable (second measurement cycle).

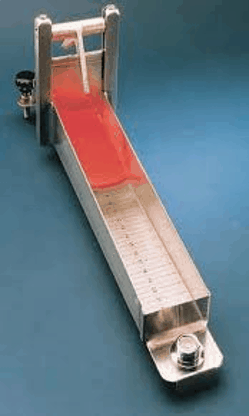

Traditional measurement of ketchup consistency: the Bostwick Consistometer

- Ketchup is allowed to flow under its own weight. Distance traveled in 30 seconds is a measure of its consistency.

- An improvised Bostwick-type trough was used in our lab to measure 3 different ketchup products. The distances flowed were:

- Ketchup 1 (a popular name brand): 13 mm

- Ketchup 2 ( a “budget” store brand): 39 mm

- Ketchup 3 (a “light” store brand): 28 mm

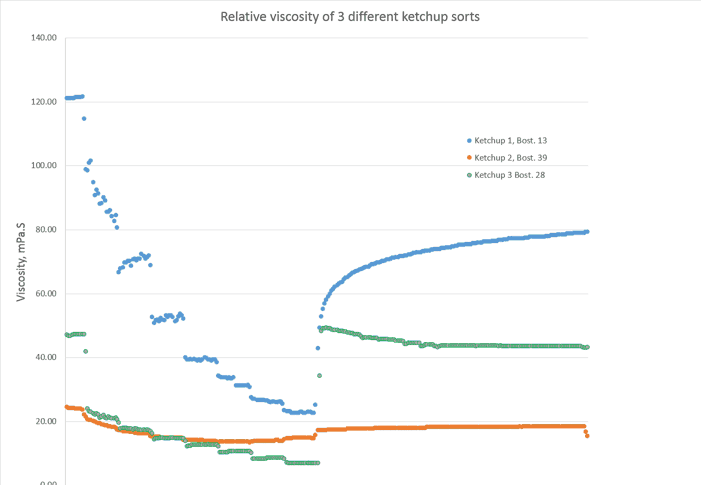

Behavior of 3 ketchups in superimposed shear measurements

- Observations

- K1 had lowest Bostwick, highest initial viscosity, and slowest recovery.

- K2 had lowest high-shear viscosity, fastest recovery.

- K3 was shear thinning at low rates, shear thickening at higher rates

- Final recovered viscosity correlated well with Bostwick consistency

Conclusions

- Superimposed shear had a large influence on indicated viscosity.

- Correlations between superimposed shear and indicated viscosity were repeatable for all three ketchup varieties.

- Each ketchup variety had a unique and repeatable “signature” response to variations in superimposed shear.

- “Recovered” indicated viscosity correlated well with Bostwick consistometer measurement, implying that this method could be used for online, inline measurements of the same properties captured by Bostwick measurements.

Open questions and future work

- How does local shear in the oscillatory boundary layer interact with global shear in the superimposed shear field?

- What can these measurements tell us about the structure of ketchup-like substances – those with yield stress and shear-dependent viscosity? In particular, why does the more highly structured material – ketchup 1 – take more time to return to a resting viscosity value than the least structured – ketchup 2?

- Future experiments will vary the relative amplitudes of shear rates in both the oscillatory and superimposed shear fields to understand both their relative contributions and the nature of their interactions.