Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process optimization. Inline monitoring of these parameters is key for a robust real-time control and to ensure quality of the end product.

Figure 1: Brine Pond for Lithium Extraction

Table of Content

- Overview

- Why is monitoring the brine’s density during the extraction process important?

- Brine density monitoring in real-time in Pond

- Installation recommendation

1. Overview

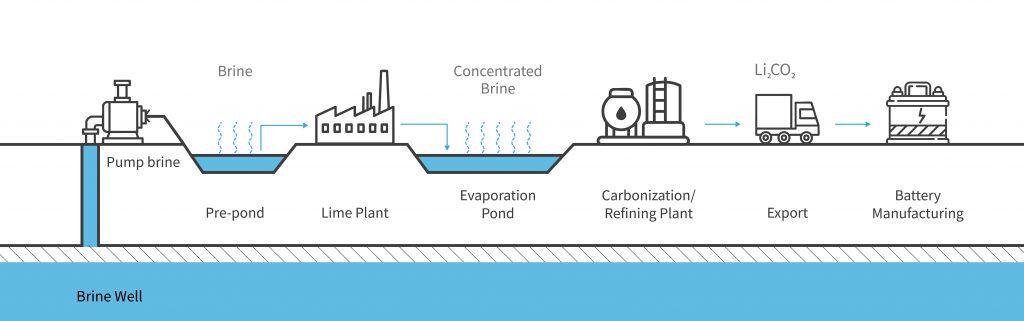

Brine is a primary source of lithium, a vital element in the production of batteries, electronics, and other technologies essential for modern energy storage.

This component is typically sourced from underground salt flats (salars), pumped to the surface, and evaporated in large ponds over months to concentrate the lithium content.

Once the desired concentration brine level is reached, it is sent to a chemical processing facility where it is exposed to purification, chemical treatment, filtration, washing, and drying to isolate and refine lithium compounds like lithium carbonate or lithium hydroxide, which are necessary raw materials for lithium-ion batteries.

This method is particularly common in regions with high concentrations of lithium in their brines, such as the “Lithium Triangle” in South America (Argentina, Bolivia, and Chile) and parts of China.

Figure 2. Brine Lithium Extraction Process

2. Why is monitoring the brine’s density during the extraction process important?

Density is a key factor in the brine lithium extraction since it helps with:

- Concentration Control:

The density parameter is directly related to the concentration of dissolved salts in the brine, including lithium salts. As water evaporates, the concentration of lithium and other salts increases, leading to a higher density.

Process Optimization:

By monitoring the density, operators can track the progress of the evaporation process and determine when the lithium concentration has reached the desired level for the next stage of processing.

Generally, brine with a higher density (higher lithium concentration) can be moved to the subsequent process, while less dense brine can remain in the pond until it reaches the desired level. This ensures efficient use of the pond system and helps optimize the overall extraction timeline.

Monitoring for Impurities:

Changes in density that are not solely attributable to lithium concentration can indicate the presence of other dissolved salts or impurities. Monitoring density can help detect these changes, prompting further analysis to identify and address potential contamination issues that could interfere with lithium recovery and the final product purity.

Control of Chemical Precipitation:

In the chemical processing stage, reagents are added to precipitate lithium compounds. The density of the brine at this stage can influence the efficiency and selectivity of the precipitation process. Maintaining the appropriate density ensures that the chemical reactions occur under optimal conditions.

3. Brine density monitoring in real-time in Pond

Rheonics SRD is an inline process sensor that can measure density, viscosity, and temperature in real time.

SRD is based on a balanced torsional resonator (BTR), unaffected by external vibrations. This technology makes the SRD a compact, light, hermetically sealed sensor probe for density applications.

Thanks to the math engine that is inside the SRD electronics, it is capable of giving real-time concentration, kinematic viscosity, dynamic viscosity, and different mathematical models.

All these benefits are used to track, monitor, and improve the Brine lithium extraction process.

Figure 3. Rheonics inline process density meter SRD

4. Installation recommendation

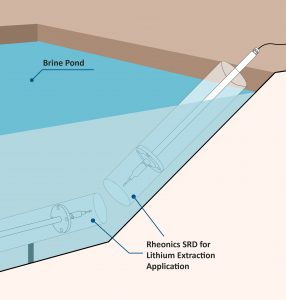

Rheonics SRD can be installed directly in the pond (Figure 4) to always measure brine density and concentration in real-time. To do this, the user has to consider the following for a smooth installation:

The SRD probe must be completely immersed in the brine pond to get representative measurements.

The sensor connector and cable must be protected from brine leakage to prevent damage to the probe.

The probe must be fixed and not moved around the pond when readings are required.

Avoid hitting the probe tip while insertion into or retraction from the pond.

Figure 4. Rheonics SRD immersed in the Brine pond

If a different installation is required, from the sensor perspective, a pond can be treated as a big tank or reservoir. The user can see all the available tank installation options here: https://support.rheonics.com/en/support/solutions/articles/81000416162-density-and-viscosity-sensor-installation-in-tank-roofs-or-lids

What’s the Rheonics standard configuration for this application?

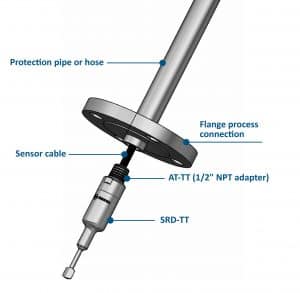

Rheonics SRD-TT (teletube variant) is used here to protect the sensor connector while providing a long insertion length

The SRD-TT together with the AT-TT (as shown in Figure 5), allows the customer to use a pipe or hose with a ½” NPT female connection as cable protection. Figure 5 shows a flanged process connection that is used for installation in the pipe laid in the pond.

The pipe with the flanged connection can be provided by Rheonics or sourced locally by the customer. Remember that the user should always use Teflon tape on NPT process connections to ensure a water-tight seal. NPT does not seal directly on metal.

Figure 5. Sensor probe configuration to be installed

How to install the SRD in the brine Pond?

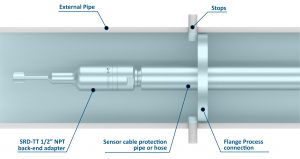

To fix the installation of the sensor in the pond, an external PVC pipe can be used with end stops that ensure a defined and constant probe insertion length in the pond, even after removal and reinstallation.

The Flange on the sensor probe helps avoid any tilting and collision of the probe with the tube wall during insertion and removal of the probe. Keep in mind that the external pipe’s inner diameter should be the same as the outer diameter of the flange process connection.

To immerse the sensor probe in the brine pond, just slide the assembly gently into the external pipe until the flange touches the stops.

To remove the SRD from the pond, pull off gently the sensor cable protection pipe or hose until the sensor probe comes out completely. Rheonics recommends that while the probe is not immersed, the sensor probe sleeve protection included in the delivery should be used to avoid unnecessary damage.

This installation solution allows easy removal of the sensor probe from the pond for inspection or cleaning if needed.

For detailed information about how to remove and immerse the Rheonics SRD in the brine pond, click here.

Figure 6. Rheonics SRD immersed in the external pipe located in the brine pond

What items can be offered by Rheonics?

| Item | Rheonics | Customer's side |

|---|---|---|

| SRD-TT | YES | NO |

| AT-TT | YES | NO |

| Protection pipe with flange process connection | YES | YES |

| External pipe and Stops | NO | YES |

If you have any doubts or inquiries, feel free to contact the Rheonic support at

Related Documentation

- Find out more about the benefits of the Rheonics SRD sensor here: Rheonics SRD

- Order now the Rheonics SRD sensor here: Rheonics SRD RFQ