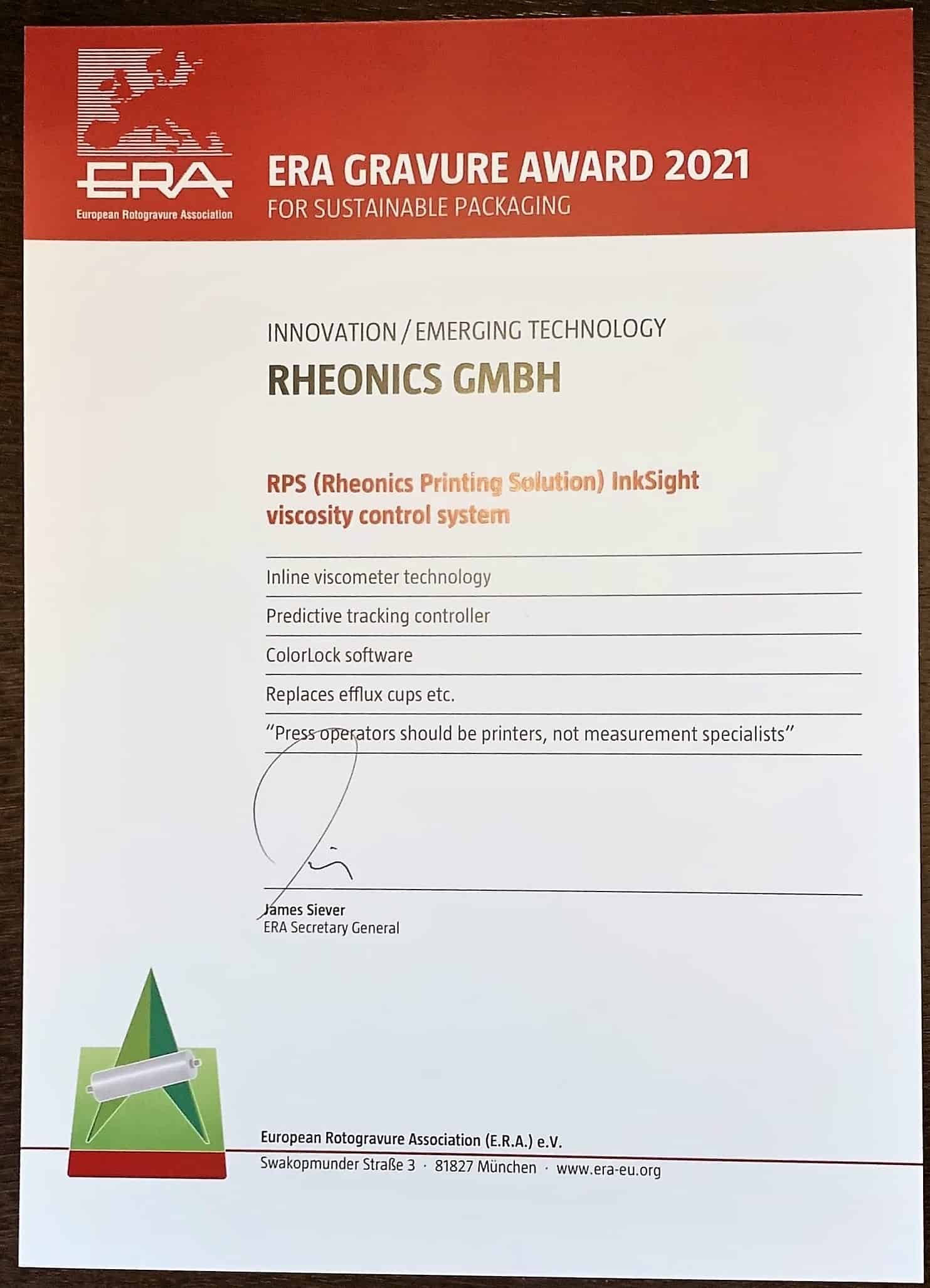

Rheonics awarded Sustainable Innovation Packaging – Innovation Prize 2021 by European Rotogravure Association

Rheonics wins a Sustainable Packaging Innovation Award by the European Rotogravure Association.

Dr. Sunil Kumar received the award at the Annual & Packaging and Decorative Gravure Conference in Thessaloniki, Greece on 21-23 September, 2021. “Gravure – the sustainable print process” was the theme of the conference, which pointed out an encouraging perspective for gravure’s future. Our viscosity automation technology ensures a high level of printing excellence and contributes to more sustainable printing operations in terms of business, environment and operator safety.

The winners of the 2021 Gravure Award for Sustainable Packaging were presented at the ERA Annual & Packaging/Decorative Gravure Conference in Thessaloniki, Greece. In the category Printed Products, the Thessaloniki-based Greek packaging printer Hatzopoulos received an award for mono-material coffee packaging printed exclusively on PP film, and the Vietnamese packaging printer Thành Phú for their dog food pouch printed on a mono-material PE/PE structure. In the category Innovation, Bobst Italia received an award for their press developments to facilitate the use of water-based inks, while the Swiss company Rheonics was rewarded with an “Emerging Technology” certificate for their new inline viscometer technology for ink viscosity measurement in the press.

Product Description: InkSight

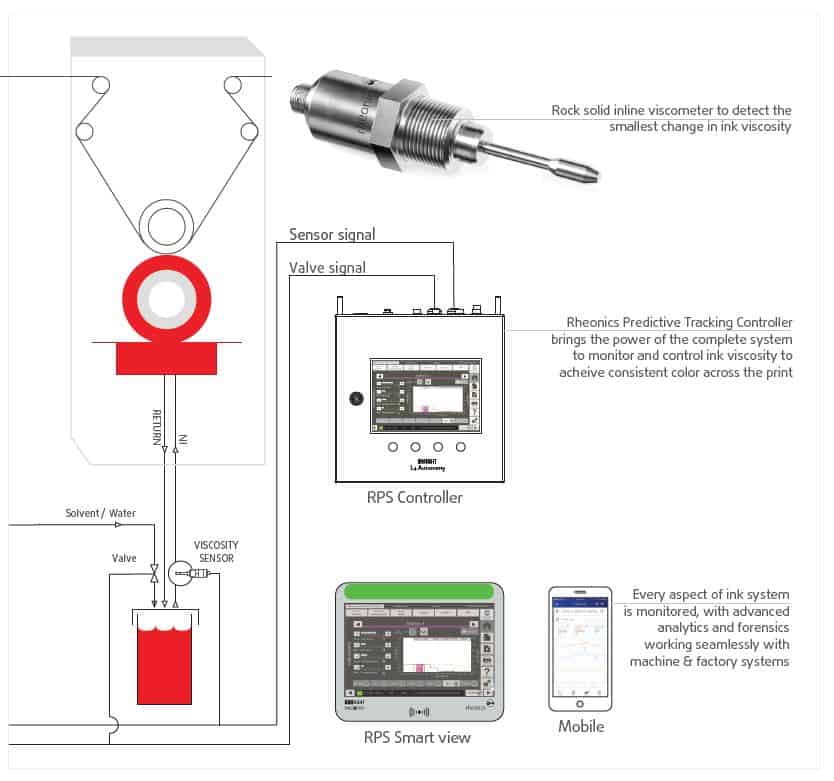

One of the most important determinants of high-quality printing is complete control of the ink viscosity. Poorly adjusted ink viscosity causes deterioration in print quality, excessive ink consumption and high rejects. Manually optimizing ink viscosity is time-consuming and often inaccurate, even for experienced press operators. Rheonics InkSight™ is a highly accurate multi-station ink viscosity control system. It consists of three subsystems, a viscosity sensor, a predictive tracking controller, and a powerful, intuitive graphical user interface. It delivers color excellence through tight automatic viscosity control. Rheonics InkSight Predictive Tracking Controller and SRV viscometers enable tight viscosity control throughout the print job, due to the system’s ability to autonomously maintain viscosity within extremely narrow limits. Printers can achieve unmatched color accuracy and quality with the InkSight system and ColorLock™ software –which is designed in collaboration with printers, for printers. Viscosity automation and predictive tracking control with InkSight reduces waste and materials consumption, as it increases efficiency and improves quality.

Innovation

Despite the highly sophisticated quality control and automation systems available on the current generation of printing machines, ink viscosity is still frequently measured with inexact and cumbersome methods, such as efflux cups and falling ball viscometers.

Continuous viscosity control with such methods is extremely inefficient and unproductive since they are not compatible with integrated solution such as the RPS InkSight for complete automation. Many common viscosity measuring devices do not provide fine enough viscosity control and require high maintenance and frequent calibration. Rheonics RPS InkSight Predictive Tracking Controller and SRV viscometers enable tight viscosity control throughout the print job, due to the the system’s ability to autonomously maintain viscosity within extremely narrow limits. Printers can achieve unmatched color accuracy and quality with the RPS InkSight system and ColorLock software – which is designed in collaboration with printers, for printers. Instead of focusing on only coarse viscosity control to pick the ink and deposit on the substrate, our breakthrough has been the fine control that gives a tight control of color throughout the print run. This has never been achieved before with other ink viscosity control systems.

Recently, we won the prestigious FTA Technical Innovation Awards 2021 for the RPS InkSight. Over the last two decades, FTA has recognized and celebrated disruptive, groundbreaking and innovative technologies impacting the package printing and the incredible achievements made by individuals and companies, large and small, which have contributed to the growth of the industry. InkSight and underlying technology is protected by granted and pending patents and trademarks.

• Rheonics SRV viscosity technology makes use of an ultra-stable torsionally balanced mechanical resonator (US patent 9,267,872 and worldwide filings) whose oscillations are damped by the viscosity of the ink.

• Further protected by US patent 10,602,670 and worldwide filings: Temperature compensated density viscosity sensor having a resonant sensing element

• Recently granted US patent 10,871,432 covering tubular sensors for inline measurement of the properties of a fluid

With over 20 patents protecting the sensors and solutions, we are well placed to protect our markets globally.

Uniqueness of the product

The Rheonics SRV inline viscometer protected by multiple Rheonics patents is one of the most commercially successful process viscometers on the market. It is deployed in industrial applications such as food processing, oil and gas, automotive, pharmaceutical, chemical and printing industries in more than 200 customer locations globally. Its unparalleled accuracy, stability and robustness provide process fluid data for optimization of industrial processes, thereby supporting data-driven decision making systems.

The new Rheonics InkSight system builds on our established product line by offering a complete ecosystem to ensure 100% viscosity control and automation within the printing press. The operators just punch a single button on the central console and the printing process runs automatically eliminating the need for operator vigilance and intervention. SRV sensors began to attract the attention of people in the printing industry who saw the potential of the accuracy, reliability and robustness of our sensors, and believed that the industry was ready to take a step in the direction of accurate, and completely automatic viscosity control.

But that step required our transition from a sensor manufacturer to a solution provider. And as we started down that path, press manufacturers and operators shared with us their vision of how tight, reliable viscosity control could unlock the potential of their technically sophisticated high-speed, automated flexographic machines to reach a new level of color reproducibility and beginning-to-end job accuracy. Their vision encouraged us to make a leap of faith to invest time and resource in developing a family of hardware and software solutions that became the InkSight system. Variants of this product family can be deployed in multiple other industries – mixing & grinding, blending, automotive and battery coating – where the process fluid viscosity should be controlled within set limits throughout.

Key competitive advantages of the RPS InkSight system, built around the SRV sensor are: ability to achieve tight color accuracy and control, ease of use and low footprint, temperature compensation algorithms, system responsiveness, control stability, intuitive reporting tools and no need to re-calibrate the sensors. The SRV viscometer– the eyes and ears of the RPS InkSight system – is a technically superior sensor that works with all types of inks. It is at least 10times more accurate than competing systems, has a very compact form factor, is certified intrinsically safe for use in explosive atmospheres, and does not require any cleaning or recalibration.

Industry Impact

Packaging and printing are interlinked in a large and fast-growing market. According to Smithers, the global value of flexographic printing will rise from $167.7 billion in 2020 to $181.1 billion in 2025. Worldwide, packaging and printing is a $350 billion market. In the coming 5-10 years, the majority of growth is expected from the dynamic packaging print sector, where new automation and hybrid press lines are needed to give flexographers more agility and ability to undertake higher value print jobs. The adoption of more sustainable printing solutions, led by water-based ink sets, and LED UV curing is expected.

Rheonics InkSight automatic ink viscosity & color control system delivers on each of these requirements and can revolutionize the flexo printing industry’s future in following ways: high print quality with all ink types, profitable short-run jobs by reducing setup times and wastes, digitalization of press, 40% reduction in VOC (volatile organic compounds) emissions, and improved operator safety.

We expect high adoption of InkSight, and a CAGR of at least 40-50 % based on: multiple key global customers in our pipeline, expansion of our global partner networks for support and sales, increased focus on industry 4.0 in printing and packaging, sensitivity to environmental norms, and significant regulatory pressure to reduce VOCs and HAPs emissions.

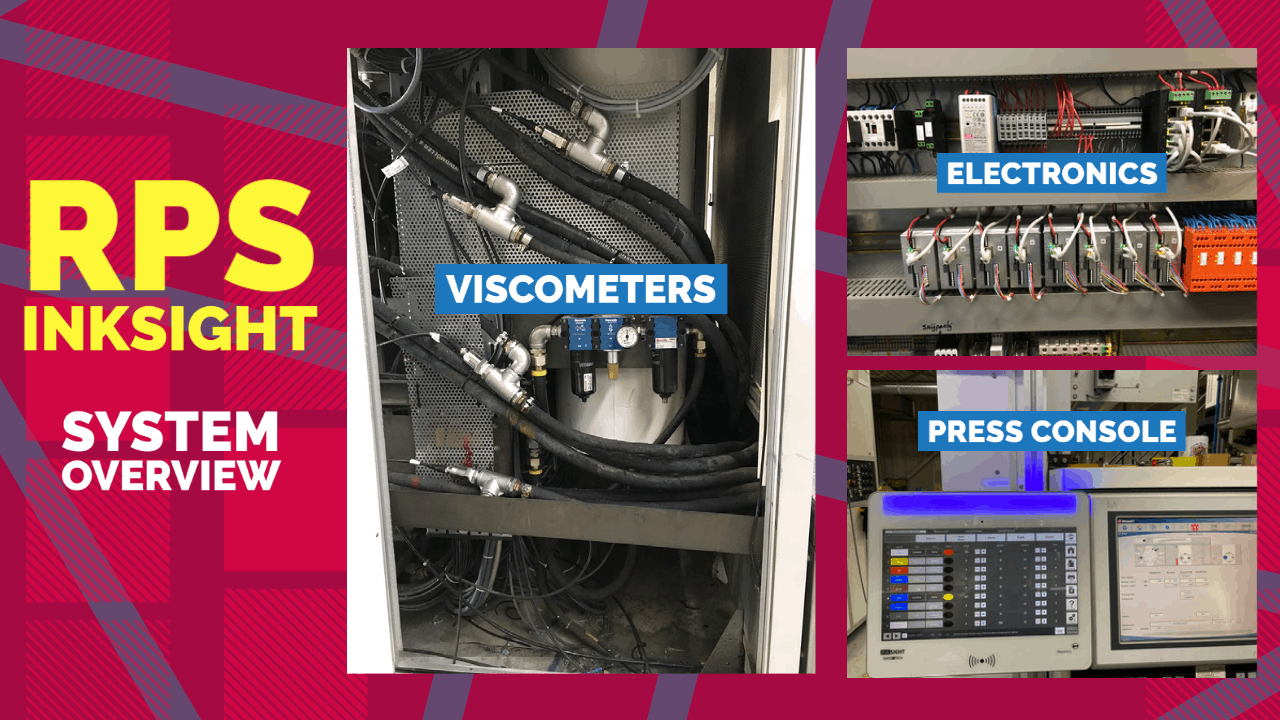

The RPS InkSight System Overview

How does the RPS InkSight System work?

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Key user benefits of the RPS InkSight

RPS places the focus on print quality instead of measurement skills.

Achieve best in class print quality, dramatically reduce setup time and optimise use of pigments and solvents. Improve productivity and efficiency through complete automation of color control on your press.

- Single click, intuitive control of ink viscosity

- Reduce setup time and eliminate setup scrap by loading previously saved job configurations, enabling consistent print quality in repeat jobs with minimal efforts for production

- Robust, maintenance free viscosity sensor eliminates need for re-calibration or cleaning by operators

- Better print quality: Tighter, more accurate color density and dE control across the complete run

- Edge over competitors by undertaking higher margin – higher quality print jobs made possible with the RPS InkSight system

Rheonics wins the prestigious Swiss Product Excellence Awards 2021

It’s an incredibly proud moment for all to announce that the Rheonics has been awarded the prestigious 2021 Swiss Product…

Rheonics InkSight Technical Webinar – Color Excellence Through Tight Viscosity Control, a 2021 FTA Technical Innovation Award Winner

Topic Color Excellence Through Tight Viscosity Control, a 2021 FTA Technical Innovation Award Winner Date & Time September 16 @…

FTA Flexo Magazine features Rheonics FTA Technical Innovation Award winning Technology – “Excellence via Viscosity Control”

Flexographic printing focused magazine - Flexo (https://www.flexography.org/flexo-magazine/) publishes an in depth article showcasing the Rheonics SRV viscometers and the RPS…

Rheonics InkSight and SRV technology wins the FTA Technical Innovation Awards 2021

It’s an incredibly proud moment for all of us here at Rheonics to announce that the Rheonics’ InkSight technology has been…