Rheonics Technical Webinar – ICI (Investment Casting Institute) – Foundry 4.0 – High Quality, Defects-Free Effective Shell Building

It is well known that the quality of casting shells is dependent on the viscosity of the shell-building slurry. This has two principal reasons. First, the viscosity is directly related to the solids content of the slurry, and reflects shifts in its composition through evaporation of the liquid component. Secondly, the performance of the slurry is directly related to its flow characteristics. The thicker the slurry – the higher its viscosity – the slower it runs off the form and the thicker the layer that it deposits. If the viscosity is too low – the slurry is too thin – it flows off the form too quickly, and the deposited layer is too thin. Since shells are formed from multiple layers, any deviations of slurry viscosity can contribute to failures of quality and performance of the shells, which can, in turn, lead to defects in the parts cast in the shells.

In order to control viscosity, it is necessary to measure it. The accuracy of control – how well the viscosity of a slurry can be set and maintained throughout the casting process – depends on the accuracy and repeatability, but also the ease of use, of the chosen measurement. The traditional measurement method is the flow cup, which measures viscosity as the number of seconds required by the slurry to run out of the cup. This measurement is not suited for continuous, repetitive monitoring of viscosity, nor is it particularly accurate. We will show how Rheonics’ SRV inline viscometer can be used for accurate, repeatable and continuous monitoring of slurry viscosity during shell building. We will then show how Rheonics’ SlurryTrack system can be used to apply the SRV’s measurements toward maintaining constant slurry viscosity during slurry preparation and shell building, despite evaporation losses, temperature changes and other influences that can cause unwanted changes to the shell quality. The SRV and SlurryTrack can, in addition, support the growing trend toward full shell-room automation, by reducing an important source of variability in the otherwise highly automated shell-building process.

Topic

Foundry 4.0 – High quality, defects-free, effective shell building needs real-time viscosity monitoring and control of ceramic slurries

Synopsis

In investment casting slurry viscosity is an important process parameter. Keeping slurry viscosity within the proper range throughout the coating step is central to forming a uniform coating thickness and desirable shell properties, as well as avoiding some of the most common shell defects. Our technical presentation, will cover the following:

- Overview of the shell building process

- How are shell properties affected by ceramic slurry viscosity?

- Why viscosity management is important in shell building?

- Types of shell defects that can be alleviated with viscosity control during the mixing process

- Process monitoring and control challenges – issues with traditional viscosity measurements

- Why investment casters are embracing Industry 4.0, data-driven processes and digitalization

- An inline sensor for simple integration in the slurry preparation drum

- Unique advantages, technical specifications, and in-depth experimental analysis on the suitability of inline sensors for ceramic slurries

Watch the Recording

Webinar by Dr. Joe Goodbread

“Foundry 4.0 – High Quality, Defects-Free Effective Shell Building”

webinar on July 13, 2021 at 11 AM EDT.

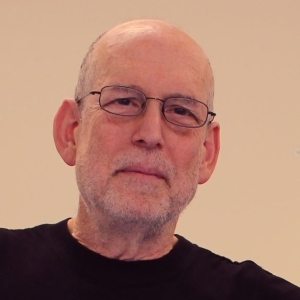

Webinar Speaker

Dr. Joe Goodbread

CTO @ Rheonics

Joe is a founding member of the team that developed Rheonics’ core technologies over the past 30 years. He established and directed the Experimental Mechanics Laboratory at the Institute for Mechanics, ETH Zurich. He has developed substantial IP in the field of fluid properties sensors with 11 granted patents and several more pending. He has a BSE in Aerospace and Mechanical Engineering Science from Princeton University, a MS in Biomechanics from Stanford University, and a Dr. Techn. Sc. from the ETH Zurich in Biomechanics. Early in his career, Joe worked with SRI (Stanford Research Institute, then) and thereafter headed the IMES labs at ETH Zurich. Joe is also a trained psychotherapist and a founder of the Institute of Process Work. He is an author of 4 books on the subject.

Joe’s extensive research and engineering skills form the technical core of the rheonics’ products and services. His passion for innovation and tackling impossible challenges has created industry leading products.

Explore Rheonics' developments in Investment Casting Industry

INCAST features Rheonics – “Foundry 4.0 – Smart Precision Casting Needs Viscosity Control of Ceramic Slurries”

Investment casting industry focused magazine - INCAST Mag (https://www.investmentcasting.org/current-issue.html) publishes a feature article covering the Rheonics inline viscometer SRV and the integrated solution - Rheonics Slurry Monitoring and Control System. The article discusses why slurry viscosity is critical in shell building and how it can monitored and controlled for building top quality, defects-free shells even under varying temperatures and evaporation…

Smart foundries – drivers for casters’ embrace of Industry 4.0 and digitalization

Many parameters can alter the ceramic slurry quality in investment casting across batches - Temperature and humidity fluctuations, mixing equipment condition, substrates, solvents, formulations, line-integration, machine interactions and time of mixing. In foundries, the downtimes and delay in deliveries involved due to rejects can hurt the profitability seriously. But what if there was a system which can continuously monitor the…

Rheonics is now member of Investment Casting Institute

We are pleased to inform you that we are now members of the Investment Casting Institute! As members of the ICI, we look forward to fruitful collaborations with industrial partners. We envision to further advance technology, ease integration of Industry4.0 solutions and process automation in investment casting application area to enable the partners within the industry deliver end-products with superior quality.…

Monitoring and controlling viscosity of ceramic slurries in investment casting

Investment castings are one of the most popular production methods for metal parts today. Investment casting process, also termed as a lost wax process, is relatively simple, which enables rapid production rates while ensuring consistent dimensional accuracy. Parts that are typically made by investment casting include those with complex geometry such as turbine blades or firearm components. High temperature applications…